Detalle Productos Cat

14567964

Minig excavators

- Machines

- Excavators

- Mining

- 6030 Hydraulic Shovel

15701348

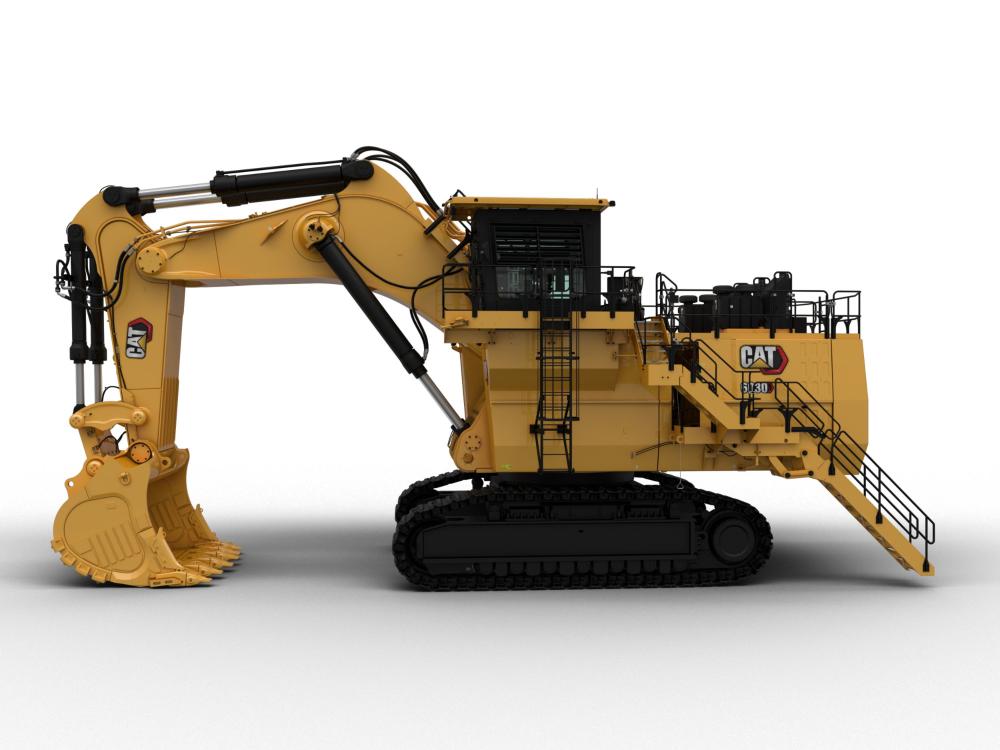

6030 Hydraulic Shovel

Caterpillar

https://www.finanzauto.es/productos/excavadoras-de-mineria-caterpillar-pala-hidraulica-6030

Metric

Imperial

Engine Output - SAE J1995

1230 kW

1649 hp

Bucket Payload

30 t

33 ton (US)

Operating Weight

294 t

324 ton (US)

Availability

The Cat® 6030 Hydraulic Mining Shovel is owned by more customers than any other product in the Cat portfolio \u2014 and for good reason. It provides the most powerful engine output in its class, along with the mobility and flexibility you need from a 300-tonne machine, to deliver the productivity you expect, with the reliability you demand.The 6030 offers a standard bucket capacity of 17 m3 (22.2 yd3) in backhoe configuration, and 16.5 m3 (21.5 yd3) in face shovel (FS) configuration with the unique Cat TriPower™ system. The 6030 is ideal to load Cat 777 to 793 mining trucks.But we\u2019re always looking for ways to make the 6030 better. The only shovel in its size class offered with dual engines, it\u2019s available with a Tier 4 Final engine solution that eliminates the need for Diesel Exhaust Fluid (DEF), saving time and cost during maintenance.

More Powerful & Productive Than Competitors

With 18% more power, up to 24% more crowd force and 17% more tearout force100% Cat Hose Assemblies

Which deliver 20 times more abrasion resistance and 2 times the durabilityMore Sustainable

Thanks to proven, efficient Cat C27 engines with non-DEF aftertreatmentSAFETY

OPERATOR CAB

RELIABILITY & DURABILITY

PRODUCTIVITY & PERFORMANCE

BUCKETS & GET

CONNECTIVITY & TECHNOLOGY

SERVICEABILITY

SUSTAINABILITY

- Safety glass in all windows and armored windshield protect operators.

- Five emergency shut-off switches, with one easily accessible in the cab to shut down the electrical system in case of emergencies.

- Safer access and egress with anti-slip walkways, 45-degree hydraulically operated access stairway and emergency egress ladder located in direct proximity to the cab.

- Safer service with lockable starter and battery isolation switch cabinet, improved routing and separation of hydraulic lines and electric cables, pressure relief caps and protective covers on all hot surfaces.

- Excellent visibility, enhanced by optional two-camera system and standard LED high-brightness working and service lights.

- Easy access to intuitive, informative onboard electronics, plus large, color touchscreen that puts vital machine and diagnostic data at the operator’s fingertips.

- Maintained ambient temperature with optional dual HVAC system.

- Easily accessible ergonomic joysticks with Electronic-Hydraulic Servo Control, which delivers dynamic and precise response and ensures no hydraulic lines are present in the cab.

- Clean arrangement and less noise, with no hydraulic lines present in the cab or the cab module,

- Pneumatically cushioned, multi-adjustable, heated seat, plus auxiliary trainer seat with retractable seat belt.

- Integrated carbody and crawler frames with Cat® HD undercarriage, which extends service life and offers improved durability and lower owning and operating costs.

- Heavy duty fixed-axle rollers and idlers for improved performance, increased wear life, reduced internal friction and overheating, and lifetime lubrication and duo cone seals for reduced maintenance.

- Heavy duty track group, which handles high field loads, and reduced pitch extension wear, which increases track chain life by 20% to 40%.

- Structures designed and fabricated to withstand the toughest digging conditions, with high-strength steel, heavy castings at attachment pivot points and booms and sticks that are stress-relieved after welding.

- Durable Cat C27 engines, which offer unsurpassed performance, high power output and proven reliability, and have been proven to withstand the challenging conditions found at mine sites across the globe.

- Greater productivity, less energy and fuel consumption and reduced wear thanks to intelligent pump managing system, which continuously evaluates actual engine and hydraulic operating values against set values and adjusts pump output accordingly.

- Reduced cycle times thanks to the use of float valves rather than engaging pumps to lower the boom, which facilitates faster boom movements and allows other operating functions such as bucket curl and stick in/out to occur simultaneously.

- Easier and faster face shovel operation with unique TriPower design, which generates superior mechanical leverage and control.

- Increased productivity and greater uptime with the twin engine concept, which enables up to 65% of full production with a single engine.

- Buckets and ground engaging tools (GET) designed to maximize durability and productivity and ideally matched to your shovel and application.

- Integrated to work as part of a machine system — helping you achieve high productivity and the lowest cost per ton.

- Variety of sizes and wear packages for the ideal match to your shovel and application.

- Deliver optimal payload when combined with Cat GET and wear components.

- Wear packages that protect your investment, including special liner material and lip shrouds, wing shrouds and heel shrouds.

- Greater connectivity with improved Product Link™ Elite system, which increases the availability of data provided by the 6030 and allows it to collect and transmit information into locally hosted or cloud-hosted applications such as Cat MineStar™ Solutions Health Office, Health Equipment Insights, or Equipment Care Advisor.

- Enhanced diagnostic capabilities and troubleshooting functions with factory-installed Monitoring and Diagnostic System.

- Earliest possible detection of faults, with Board Control System that uses sensors throughout the machine to monitor operating data, record faults, and notify the operator audibly and visually.

- Better organized hoses and components, plus integration of Cat hoses and couplings, which offer industry-leading reliability and performance and ability to source locally using all Cat materials.

- Service station that provides easy access to functions such as coolant, hydraulic oil, slew gear box oil, grease, and diesel and engine oil.

- Reduced maintenance downtime thanks to exchange intervals for engine oil and engine filters that have been increased from 500 to 1,000 hours.

- Clear arrangement of components on the superstructure, which allows easy access and serviceability for coolant expansion tanks, air intake filters, oil tank breather, HVAC units, grease tank, exhaust, and starter and battery isolator.

- Access to Cat Electronic Technician (ET), which enables easy diagnosis of potential engine problems and can help prevent future issues.

- Highly regulated C27 engines that meet U.S. EPA Tier 4 Final and EU Stage V emission requirements and eliminate the need for DEF, saving time and cost during maintenance.

- Less heat and improved efficiency with the closed-loop swing circuit.

- Reduced waste and lower owning and operating costs thanks to increased commonality of systems and components, plus a reduction in unique part numbers.

- Preservation of raw materials, energy conservation and reduced emissions through the Cat Reman program, which returns end-of-life components to like-new condition.

General

| Engine Output - SAE J1995 | 1230 kW | 1649 hp |

| Bucket Payload | 30 t | 33 ton (US) |

| Operating Weight | 294 t | 324 ton (US) |

| Note | Specifications shown above apply to the highly regulated Face Shovel configuration. Backhoe and Frontless configurations are also available for all regions. |

Diesel Engine - Highly Regulated

| Gross Power - SAE J1995 | 1230 kW | 1649 hp |

| Net Power - ISO 9249 | 1212 kW | 1625 hp |

| Net Power - SAE J1349 | 1149 kW | 1541 hp |

| Emissions | Meets U.S. EPA Tier 4 Final and EU Stage V emission standards |

Diesel Engine - Lesser Regulated

| Gross Power - SAE J1995 | 1142 kW | 1531 hp |

| Net Power - SAE J1349 | 1063 kW | 1425 hp |

| Net Power - ISO 9249 | 1127 kW | 1511 hp |

| Emissions | Meets China Nonroad Stage III emission standards, equivalent to U.S. EPA Tier 2 |

Diesel Engines

| Number of Cylinders - Each Engine | 12 | |

| Bore | 137.7 mm | 5.42 in |

| Stroke | 152.4 mm | 6 in |

| Displacement | 27 l | 1648 in³ |

| Aspiration | Turbocharged and air-to-air aftercooled | |

| Components (1) | Hydraulically driven radiator fan with electronically controlled fan speed | |

| Components (2) | Micro processed engine management | |

| Components (3) | Heavy-duty air filters | |

| Components (4) | Two-stage fuel filter, including water separator | |

| Components (5) | Additional high-capacity water separator | |

| Emissions | Meets U.S. EPA Tier 4 Final and EU Stage V emission standards | |

| Fuel Tank Capacity | 5080 l | 1342 gal (US) |

Electrical System - Diesel Drive

| System Voltage | 24V |

| Batteries in Series/Parallel Installation | 4 x 210 Ah at 12V each; 420 Ah with 24V in total |

| Components (1) | Battery isolation relays |

| Components (2) | Emergency stop switches accessible from ground level and in engine module |

| Components (3) | 14 LED high-brightness working flood lights |

| Components (4) | 11 LED service lights |

Electrical System

| Batteries | 4 maintenance-free batteries |

Operating Weights

| 6030 FS - Standard Track Pads | 1000 mm | 3.25 ft |

| 6030 FS - Operating Weight | 298300 kg | 657640 lb |

| 6030 FS - Ground Pressure | 22.2 N/cm² | 32.2 psi |

| 6030 - Standard Track Pads | 1000 mm | 3.25 ft |

| 6030 - Operating Weight | 299400 kg | 660060 lb |

| 6030 - Ground Pressure | 22.3 N/cm² | 32.3 psi |

| Note | Other track pads available on request. Operating weights include: base machine, front attachment, standard track pads, standard rock bucket, and 100% fuel and lubricants. |

Hydraulic System with Pump Managing System

| Hydraulic Tank Capacity - Approximately | 2675 l | 707 gal (US) |

| Total Volume of Hydraulic Oil - Approximately | 3500 l | 925 gal (US) |

| Main Pumps | 4 x variable swash plate pumps | |

| Main Pumps - Maximum Oil Flow - Diesel Version | 4 x 552 L/min (4 x 146 gal/min) | |

| Maximum Pressure - Attachment | 310 bar | 4495 psi |

| Maximum Pressure - Travel | 360 bar | 5220 psi |

| Swing Pumps | 2 x reversible swash plate double pumps | |

| Swing Pumps - Maximum Oil Flow - Diesel Version | 4 x 197 L/min (4 x 52 gal/min) | |

| Maximum Pressure - Swing Pumps | 350 bar | 5076 psi |

Hydraulic Oil Cooling

| Oil Flow of Cooling Pumps - Diesel Version | 2 x 467 L/min (2 x 123 gal/min) | |

| Diameter - Fan | 1220 mm | 48 in |

Swing System

| Swing Drive | 2 compact planetary transmissions with axial piston motors | |

| Parking Brakes | Wet multiple-disc brake, spring-loaded/hydraulically released | |

| Maximum Swing Speed - Diesel Version | 4.6 r/min | 4.6 r/min |

| Swing Ring | Triple-race roller bearing with sealed internal gearing | |

| Maximum Swing Speed - AC Version | 5 r/min | 5 r/min |

Undercarriage

| Travel Speed - 1st Stage - Maximum | 1.4 km/h | 0.87 mile/h |

| Travel Speed - 2nd Stage - Maximum | 2.7 km/h | 1.68 mile/h |

| Maximum Tractive Force | 1602 kN | 360144 ft·lbf |

| Gradeability - Travel Drives - Approximate | 47 % | 47 % |

| Track Pads - Each Side | 44 | |

| Bottom Rollers - Each Side | 7 | |

| Support Rollers - Each Side | 2 plus a skid plate in between | |

| Travel Drives - Each Side | 1 planetary transmission with 2 two-stage axial piston motors | |

| Parking Brakes | Wet multiple disc brake, spring loaded/hydraulically released | |

| Components (1) | All running surfaces of sprockets, idlers, rollers and pad links, as well as teeth contact areas of sprocket and pad links, are hardened | |

| Components (2) | Cast double-grouser combined pad-links with bushings connected by hardened full floating pins | |

| Components (3) | Fully hydraulic self-adjusting track tensioning system with membrane accumulator | |

| Components (4) | Automatic hydraulic retarder valve to prevent over-speed on downhill travel | |

| Components (5) | Acoustic travel alarm |

Operator's Cab

| Operator's Eye Level - Approximately | 6.5 m | 21.33 ft |

| Internal Dimensions of Cab - Length | 2200 mm | 7.22 ft |

| Internal Dimensions of Cab - Width | 1600 mm | 5.25 ft |

| Internal Dimensions of Cab - Height | 2150 mm | 7.05 ft |

| Components (1) | Under roof mounted heating ventilating and air conditioning system | |

| Components (2) | External sun shields at side and rear windows | |

| Components (3) | Robust instrument panel including large colored BCS screen with transflective technology | |

| Components (4) | Board Control System (BCS) electronic monitoring and data logging system for vital signs and service data of engines, hydraulic system and lubrication system | |

| Components (5) | Hydraulically operated 45 degree access stairway | |

| Components (6) | Emergency egress ladder with ladder cage | |

| Components (7) | Switch in seat cushion to automatically neutralize the hydraulic controls when operator leaves the seat | |

| Components (8) | Pneumatically cushioned and multi-adjustable comfort seat with lumbar support, seat heating, safety belt, head- and armrests | |

| Components (9) | Roller blinds at all windows | |

| Components (10) | Windshield with parallel intermittent wiper/washer | |

| Components (11) | All-round safety glass, armored windshield and sliding side window | |

| Components (12) | Operator Protective Guards (ISO 10262:1998 Level II | |

| Components (13) | Joystick controls integrated in independently adjustable seat consoles | |

| Components (14) | Fold-away auxiliary seat with safety belt |

Automatic Lubrication System

| Capacity - Grease Container | 450 l | 119 gal (US) |

| Type (1) | Dual-circuit system with hydraulically driven heavy-duty pump and electronic time relay control to adjust the pause/lube times | |

| Type (2) | Connected to the lubrication system are the swing roller bearing with internal gearing and all pivot points of attachment, bucket and cylinders | |

| Type (3) | Lubricated pinion for greasing of internal gearing of swing ring | |

| Type (4) | System failures displayed by Board Control System | |

| Type (5) | Grease filters between service station and container as well as directly behind grease pump |

Bucket

| Bucket Capacity - Face Shovel (heaped 2:1) | 16.5 m³ | 21.6 yd³ |

| Bucket Capacity - Backhoe (heaped 1:1) | 17 m³ | 22.2 yd³ |

Digging Forces

| Maximum Crowd Force | 1298 kN | 291700 ft·lbf |

| Maximum Tearout Force | 944 kN | 212150 ft·lbf |

Attachments

| Shovel attachment with unique TriPower kinematics ensuring the following main features: (1) | Automatic roll-back limiter to prevent material spillage and kinematic assistance to hydraulic forces |

| Shovel attachment with unique TriPower kinematics ensuring the following main features: (2) | Horizontal automatic constant-angle bucket guidance and vertical automatic constant-angle bucket guidance |

| Shovel attachment with unique TriPower kinematics ensuring the following main features: (3) | Constant boom momentum throughout the whole lift arc and crowd force assistance |

| All buckets (FS and BH) are equipped with a wear package consisting of: (1) | Special liner material covering main wear areas inside and outside of bucket and lip shrouds between teeth |

| All buckets (FS and BH) are equipped with a wear package consisting of: (2) | Wing shrouds on side walls and heel shrouds at bottom edges |

| Type (1) | Catwalks with rails at booms |

| Type (2) | Special wear packages for highly abrasive materials on request |

| Type (3) | Pressure-free lowering of boom (FS and BH) and stick (FS) by means of a float valve |

| Type (4) | Welding procedures allow for internal counter-welding (double prep weld) wherever possible |

| Type (5) | Booms and sticks are stress-relieved after welding |

| Type (6) | Booms and sticks are torsion-resistant, welded box design of high-tensile steel with solid steel castings at pivot areas |

You might also be interested in:

-

6015

Engine Output - SAE J1995

615 kW

824 hp

Bucket Payload

14.6 t

16.1 ton (US)

Operating Weight

140 t

154.3 ton (US)

Cat

15196763

-

6020

Engine Output - SAE J1995

776 kW

1040 hp

Bucket Payload

21.6 t

23.8 ton (US)

Operating Weight

230.2 t

253.8 ton (US)

Caterpillar

15701239

-

6040

Engine Output - SAE J1995

1550 kW

2079 hp

Bucket Payload

39.6 t

43.7 ton (US)

Operating Weight

404.6 t

446 ton (US)

Cat

15701534

-

6060

Engine Output - SAE J1995

2248 kW

3015 hp

Bucket Payload

61 t

67 ton (US)

Operating Weight

599 t

660 ton (US)

Cat

15701749

Other categories of Excavadoras:

360º Interior

360º Exterior

Virtual Tour

6030 Hydraulic Shovel

Call us

I am interested

I am interested

Thank you for contacting us.

We have received your request and will contact you as soon as possible.

Please check your email to ensure that the form has been sent correctly.